Introduction to Edge Emitting Laser (EEL)

In order to obtain high-power semiconductor laser output, the current technology is to use edge emission structure. The resonator of the edge-emitting semiconductor laser is composed of the natural dissociation surface of the semiconductor crystal, and the output beam is emitted from the front end of the laser.The edge-emission type semiconductor laser can achieve high power output, but its output spot is elliptical, the beam quality is poor, and the beam shape needs to be modified with a beam shaping system.

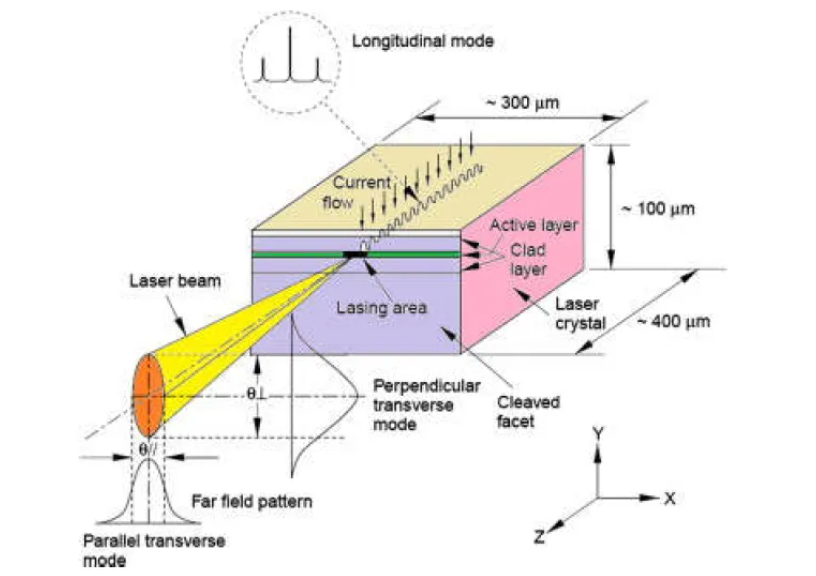

The following diagram shows the structure of the edge-emitting semiconductor laser. The optical cavity of EEL is parallel to the surface of the semiconductor chip and emits laser at the edge of the semiconductor chip, which can realize the laser output with high power, high speed and low noise. However, the laser beam output by EEL generally has asymmetric beam cross section and large angular divergence, and the coupling efficiency with fiber or other optical components is low.

The increase of EEL output power is limited by waste heat accumulation in active region and optical damage on semiconductor surface. By increasing the waveguide area to reduce the waste heat accumulation in the active region to improve the heat dissipation, increasing the light output area to reduce the optical power density of the beam to avoid optical damage, the output power of up to several hundred milliwatts can be achieved in the single transverse mode waveguide structure.

For the 100mm waveguide, a single edge-emitting laser can achieve tens of watts of output power, but at this time the waveguide is highly multi-mode on the plane of the chip, and the output beam aspect ratio also reaches 100:1, requiring a complex beam shaping system.

On the premise that there is no new breakthrough in material technology and epitaxial growth technology, the main way to improve the output power of a single semiconductor laser chip is to increase the strip width of the chip’s luminous region. However, increasing the strip width too high is easy to produce transverse high-order mode oscillation and filamentlike oscillation, which will greatly reduce the uniformity of light output, and the output power does not increase proportionally with the strip width, so the output power of a single chip is extremely limited. In order to greatly improve the output power, array technology comes into being. The technology integrates multiple laser units on the same substrate, so that each light emitting unit is lined up as a one-dimensional array in the slow axis direction, as long as the optical isolation technology is used to separate each light emitting unit in the array, so that they do not interfere with each other, forming a multi-aperture lasing, you can increase the output power of the entire chip by increasing the number of integrated light emitting units. This semiconductor laser chip is a semiconductor laser array (LDA) chip, also known as a semiconductor laser bar.

Post time: Jun-03-2024