The working principle and main types of semiconductor laser

Semiconductor Laser diodes, with their high efficiency, miniaturization and wavelength diversity, are widely used as core components of optoelectronic technology in fields such as communication, medical care and industrial processing. This article further introduces the working principle and types of semiconductor lasers, which is convenient for the selection reference of the majority of optoelectronic researchers.

1. The light-emitting principle of semiconductor lasers

The luminescence principle of semiconductor lasers is based on the band structure, electronic transitions and stimulated emission of semiconductor materials. Semiconductor materials are a type of material with a bandgap, which includes a valence band and a conduction band. When the material is in the ground state, electrons fill the valence band while there are no electrons in the conduction band. When a certain electric field is applied externally or a current is injected, some electrons will transition from the valence band to the conduction band, forming electron-hole pairs. During the process of energy release, when these electron-hole pairs are stimulated by the outside world, photons, that is, lasers, will be generated.

2. Excitation methods of semiconductor lasers

There are mainly three excitation methods for semiconductor lasers, namely electrical injection type, optical pump type and high-energy electron beam excitation type.

Electrically injected semiconductor lasers: Generally, they are semiconductor surface-junction diodes made of materials such as gallium arsenide (GaAs), cadmium sulfide (CdS), indium phosphide (InP), and zinc sulfide (ZnS). They are excited by injecting current along the forward bias, generating stimulated emission in the junction plane region.

Optically pumped semiconductor lasers: Generally, N-type or P-type semiconductor single crystals (such as GaAS,InAs,InSb, etc.) are used as the working substance, and the laser emitted by other lasers is used as the optically pumped excitation.

High-energy electron beam-excited semiconductor lasers: Generally, they also use N-type or P-type semiconductor single crystals (such as PbS,CdS,ZhO, etc.) as the working substance and are excited by injecting a high-energy electron beam from the outside. Among semiconductor laser devices, the one with better performance and wider application is the electrically injected GaAs diode laser with a double heterostructure.

3. The main types of semiconductor lasers

The Active Region of a semiconductor laser is the core area for photon generation and amplification, and its thickness is only a few micrometers. Internal waveguide structures are utilized to restrict the lateral diffusion of photons and enhance energy density (such as ridge waveguides and buried heterojunctions). The laser adopts a heat sink design and selects high thermal conductivity materials (such as copper-tungsten alloy) for rapid heat dissipation, which can prevent wavelength drift caused by overheating. According to their structure and application scenarios, semiconductor lasers can be classified into the following four categories:

Edge-Emitting Laser (EEL)

The laser is output from the cleavage surface on the side of the chip, forming an elliptical spot (with a divergence Angle of approximately 30°×10°). Typical wavelengths include 808nm (for pumping), 980 nm (for communication), and 1550 nm (for fiber communication). It is widely used in high-power industrial cutting, fiber laser pumping sources, and optical communication backbone networks.

2. Vertical Cavity Surface Emitting Laser (VCSEL)

The laser is emitted perpendicularly to the surface of the chip, with a circular and symmetrical beam (divergence Angle <15°). It integrates a distributed Bragg reflector (DBR), eliminating the need for an external reflector. It is widely used in 3D sensing (such as mobile phone face recognition), short-range optical communication (data centers), and LiDAR.

3. Quantum Cascade Laser (QCL)

Based on the cascade transition of electrons between quantum Wells, the wavelength covers the mid-to-far-infrared range (3-30 μm), without the need for population inversion. Photons are generated through intersubband transitions and are commonly used in applications such as gas sensing (such as CO₂ detection), terahertz imaging, and environmental monitoring.

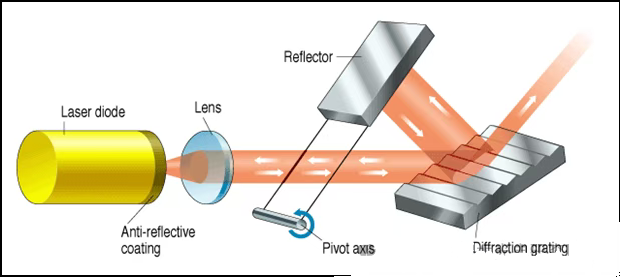

The tunable laser’s external cavity design (grating/prism /MEMS mirror) can achieve a wavelength tuning range of ±50 nm, with a narrow linewidth (<100 kHz) and a high side-mode rejection ratio (>50 dB). It is commonly used in applications such as dense wavelength division multiplexing (DWDM) communication, spectral analysis, and biomedical imaging. Semiconductor lasers are widely used in communication laser devices, digital laser storage devices, laser processing equipment, laser marking and packaging equipment, laser typesetting and printing, laser medical equipment, laser distance and collimation detection instruments, laser instruments and equipment for entertainment and education, laser components and parts, etc. They belong to the core components of the laser industry. Due to its wide range of applications, there are numerous brands and manufacturers of lasers. When making a choice, it should be based on specific needs and application fields. Different manufacturers have different applications in various fields, and the selection of manufacturers and lasers should be made according to the actual application field of the project.

Post time: Nov-05-2025